- Home

- Electropolishing

What is Electropolishing?

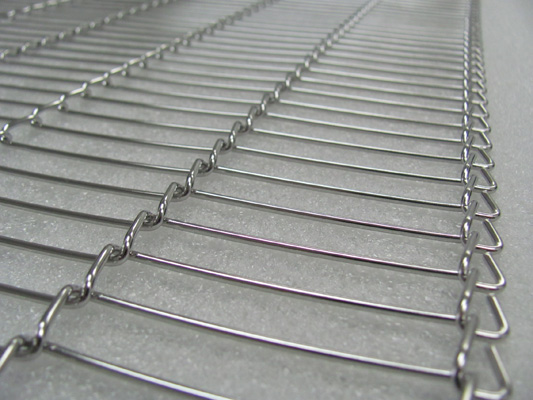

Electropolishing is an electrochemical process by which surface material is removed by anodic dissolution. Electropolishing removes surface material, beginning with the high points within the microscopic surface texture. By removing these points, the electropolishing process will improve the surface finish of a metal such as stainless steel, nickel, and Hastelloy, leaving a smoother and more reflective surface. Common parts and components electropolished include tanks, piping, fittings, rods, discs, large parts & surfaces, and more.

The Benefits of Electropolishing

The benefit of electropolishing is that it delivers a smoother, more reflective surface that reduces product adhesion and improves surface cleanability. Perhaps more importantly, electropolishing preferentially dissolves free iron, inclusions, and embedded particles from the surface of the work-piece. This process improves the near-surface chemistry of the material and promotes the formation of an improved corrosion resistant surface layer.

Harrison Electropolishing is a leading provider of electropolishing services for industrial and high purity industries. Since our opening in 1980 we have continually worked to expand and improve our services. Today, with over 50 employees and expanded operating hours, Harrison Electropolishing is well suited to provide electropolish services for a multitude of industries.

INDUSTRY STANDARDS

-

ASTM B912

Standard Specification for Passivation of Stainless Steal Using Electropolishing

-

SEMI F17

Specification for High Purity Quality Electropolished 316L Stainless Steal Tubing, Component Tube Stubs and Fittings Made from Tubing

-

SEMI F19

Specification for wetted surface finishes of electropolished 316L stainless steal components

-

ASME BPE

Specification for bioprocessing equipment in the pharmaceutical industry, components of a distribution system or conveyor belts

Electropolishing Process

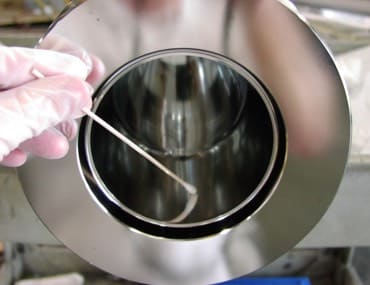

Electropolishing is accomplished by creating an electrochemical cell in which the material to be polished is charged anodically. A cathode is formed to mirror the geometry of the work-surface and the two are submerged in a heated electrolyte bath. When a DC current is applied, the electrical charge forces metal ions to be dissolved from the stainless steel work-surface. Depending on the runtime of the electropolishing process and the dimensional tolerances of the component to be electropolished, the amount of material that can be removed ranges from 0.0003” to 0.003”.

Prior to Electropolishing

The key to the electropolishing process is the difference in current density across the surface. Within the microscopic surface profile, the current density is greater at the high points and lesser at the low points. The rate of the electropolishing reaction is directly proportional to the current density. The increased current density at the raised points forces the metal to dissolve faster at these points and thus tends to level the surface material. After the electropolishing treatment, the work-piece is passed through a series of steps to neutralize, rinse, clean and dry the surfaces.

Electropolishing Capabilities

Our capabilities allow us to process components of all sizes. While most process equipment may fit within our electropolishing tanks, we have developed proprietary techniques in order to electropolish larger components. These proprietary techniques allow us to process equipment of any size at our facility or in the field

Electropolishing Facility

- 25,000 square foot facility, expanded and updated in 2021

- 360 square foot class 1000 cleanroom

- Four overhead cranes

- 15,000lbs material handling capability

- Four fulltime electropolishing lines

- Expanded operating tanks

Electropolishing Applications

Harrison is a leader in electropolishing services for the following industries and applications: